CBI

6400CT

Horizontal Grinder

Horizontal Grinder

Backed with

Aftermarket support

The CBI Magnum Force 6400CT Horizontal Grinder is an extreme-duty machine engineered for resilience and high production when grinding contaminated demolition debris, railroad ties, whole trees, pallets, storm debris, shingles, logs, mulch, slash, and stumps. Built from a fully welded and line bored hog box, this yellow monster thrives more than any other horizontal grinder when processing high amounts of tough material.

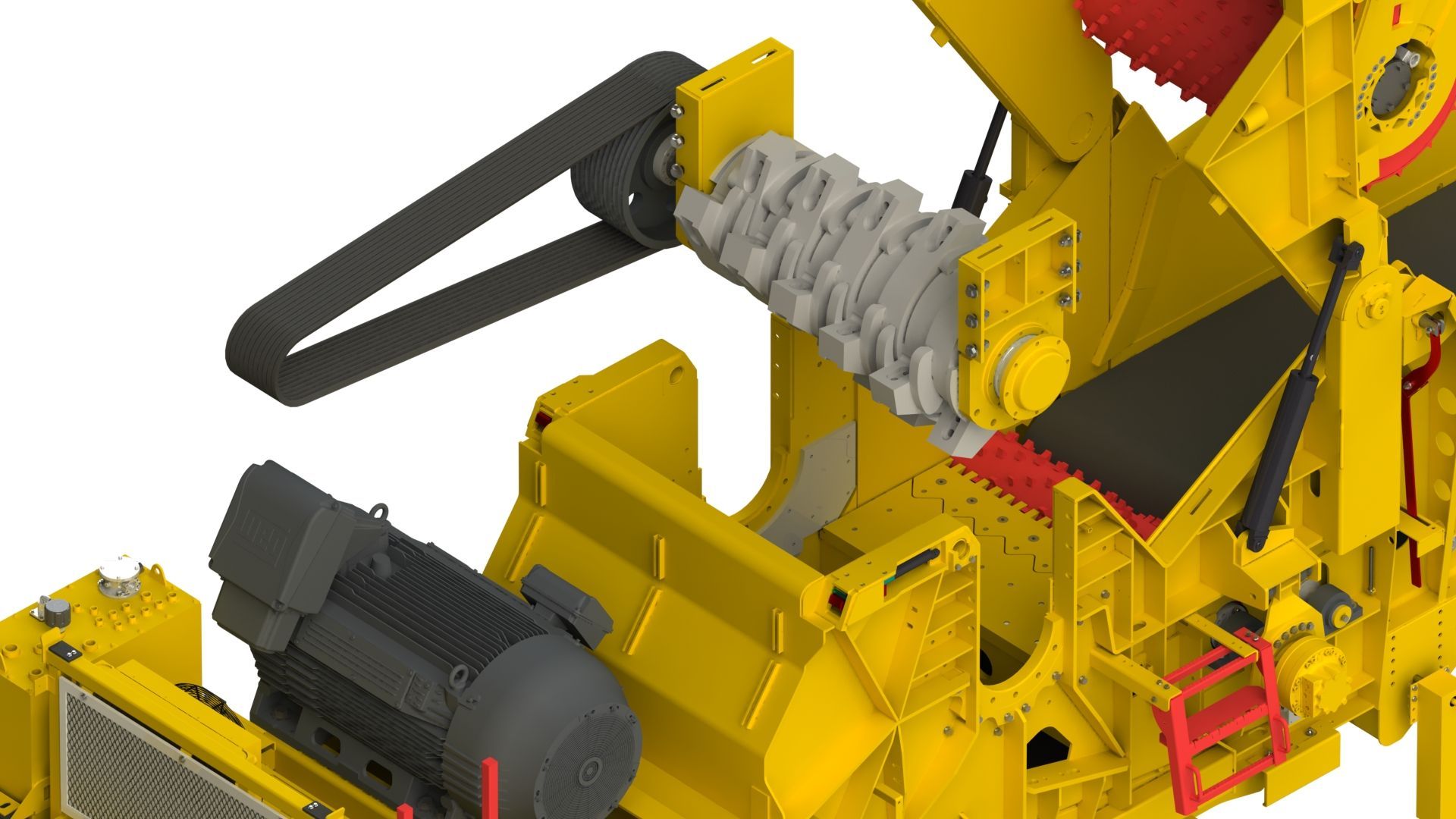

The revolutionary new “cassette style” clam shell design allows end-users to completely swap out rotors faster than any other grinder in its class. Go from grinding to chipping in half the time as before, and know you can accept jobs with various material demands. Four interchangeable rotors give this horizontal grinder the versatility needed to stay on top of changing markets. Enhancing the 6400T’s industry-leading design, this horizontal grinder supports either a CAT C27 1050hp T4 engine or CAT C32 1200hp T4 engine by relying on the larger, more durable, shaft and bearings assembly. The design of the CBI offset helix rotor minimizes energy loss from each strike and distributes material evenly across the rotor, efficiently out producing the competition.

The new and improved user interface allows operators to adjust and save multiple groups of feed speeds, pressures, and automated control systems to guarantee the most efficient performance across a wide range of materials. A brand new feature called T-link (Terex Telematics System) comes standard on all of our grinders. T-Link allows owners to remotely monitor detailed reports of operating data, machine status, alarms, and other key metrics. This system provides the customer with a customizable online dashboard which displays a full range of data and can also be configured to send email and text notifications when certain events occur. T-Link technology will continue to expand, giving our customers a best-in-class experience with service and parts.

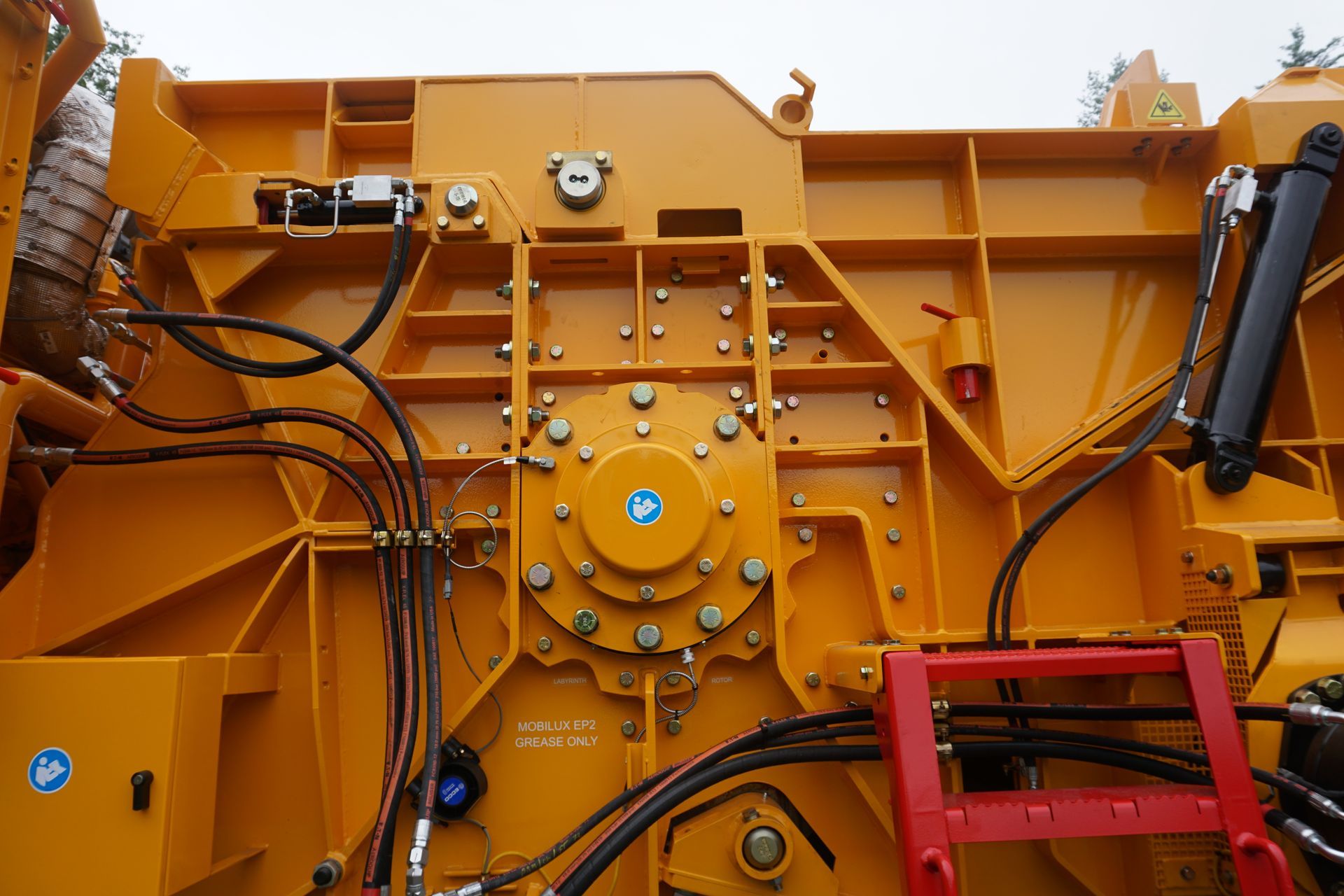

The hydraulic filter rack is strategically located to be fully accessible at ground level, with a sloped design to help shed materials which build up in the field. All of the valve decks have stainless steel guarding to protect the unit while tracking through overgrown areas. To top it off, we’ve moved the hydraulic tank higher on the unit and increased capacity to ease strain on the pumps. Speed sensors have been added to the feed system for a more continuous and efficient pace of grinding, especially when using CBI IntelliGrind. Access to the outer face of the outside hammers is now as simple as opening the hog box. The upper profile change of the box leaves the hammer fully exposed for maintenance at the “crotch” of where the top feed roll arm rests.

Technical Specifications

DISCHARGE CONVEYOR

Width: 60” (1.5 m)

Length: 37’ (11.2 m)

Height: 16’-7” (5 m)

Discharge belt has optional magnetic head pulley and chute

INFEED

Width: 60” (1.5 m)

Height: 6’-11” (2.1 m)

Conveyor: 15’ (4.5 m), heavy-duty belting

HYDRAULICS

Hydrostatic

Hydraulic capacity 95 gallons (359 L)

EQUIPMENT PROTECTION

Metal Detection SystemTM (MDS)

HAMMERMILL

Diameter: 40” (1 m)

Width: 60” (1.5 m)

Shaft: 6” (0.15 m)

Top Feed Roll: 40” diameter x 60”

TRANSPORT DIMENSIONS

Height 3.65m | Width 3.28m | Length 13.3m | 47,000kg

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton